Powder Filling & Sealing Machine

- Are you in the market for packaging solutions for powders? VKPAK offers a powder filling machine line which is ideal for everything from chemicals to spices. We supply both automatic and semi-automatic equipment which has been proven to be safe and effective.

- Mesin pangisi auger lan mesin isi lan segel wangun liyane sing njamin nggawe produk kaya gula, susu bubuk, bubuk, lan glepung diisi kanthi akurat. Apa sampeyan duwe fasilitas produksi anyar, sampeyan wis nggedhekake macem-macem produk, utawa sampeyan kudu ngganti peralatan sing lawas, mesin ngisi bubuk modern bakal ningkatake operasi sampeyan. Sampeyan bakal bisa ngeposake produk kanthi luwih efisien lan alur produksi

Ndeleng Video

Mesin Pangisi & Powder Oaling otomatis otomatis

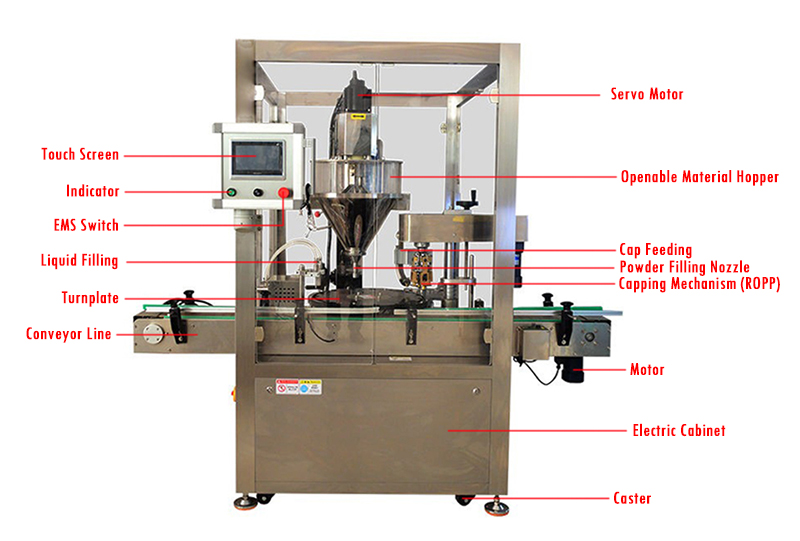

- The VK-PAF Automatic powder auger filling and capping machine is application for automatic filling powder

- Menyang botol, bokor lan kaleng, banjur cop otomatis (nutup) otomatis. Iku mesin monoblock.

- The main products are glitter powder, pepper, cayenne pepper, milk powder, rice flour, albumen powder,soy milk powder, coffee powder, medicine powder ,additive, essence and spice, etc It can connnect with a bottle feeding table or bottle unsrambler from start, and connection with VK-VRL round bottle labeling machine or VK-DSL double side labeling machine being a full automatic packaging lines.

Ndeleng Video

Fitur

- Model GMP kompak.

- Unit kasebut digawe kompak & serbaguna kaya norma-norma saiki.

- Kabeh bagean kontak sing digawe saka Stainless Steel 316 sing bermutu.

- Awak mesin kanthi elegan rampung saka Stainless Steel 304.

- Sabuk conveyor slat digawe saka Stainless Steel 304.

- "Ora ana Cartridge - Ora Isi" kanggo ngindhari cairan sing larang regane.

- Akurasi Isi sing dhuwur saka 0. 1% ing dosis siji.

- Plugging tanpa ninggalake plug ing cartridges.

- Sistem paling anyar milih.

- Katelu telung operasi ing siji platform, mula butuh syarat spasi.

Ndeleng Video

Keuntungan

- 1.Servo motor mimpin, Siemens PLC lan layar tutul

- 2.Tambah karo feeder bubuk kanthi otomatis kanggo bubuk dadi hopper

- 3. Ditampa karo tutup bledug lan sistem nyedhot bledug nalika ngisi bubuk.

- 4.IT nambah nozzle ngiseni lan sirah capping kanggo nambah kapasitas kerja

Ndeleng Video

Parameter Teknis

| Model | VK-PAF-1 | VK-PAF-2 |

| Dhiameter botol | Φ15-80mm (ngatur) | |

| Dhuwur botol | 15-150mm (ngatur) | |

| Bobot ngiseni | 1 - 5g, 5-30g, 30-100,100-500g | |

| Akurasi Isi | ≤ 100g, ≤ ± 2%; 100 - 500g , ≤ ± 1% | |

| Kacepetan Isi | 15 - 35bote / min | 30 - 70 botol / min |

| Daya Bekase | 3phase AC380V 50 / 60Hz | |

| Masokan Udara | 6 kg / cm2 0,05m3 / min | |

| Gunggung Daya | 1.8Kw | 2.3Kw |

| Bobot total | 450kg | 550kg |

| Ukuran Sakabèhé | 1400 × 1120 × 1850mm | 1700 × 1420 × 2000mm |

| Jilid Hopper | 35L | 25L (rong hoppers) |

Ndeleng Video

Fleksibel

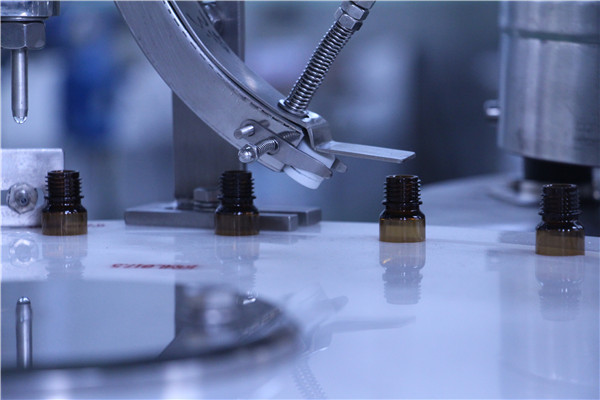

- Keluwesan luar biasa adaptasi kanggo botol cilik

- Cairan e-rokok, tetes mata lan produk penisilin

- Conveyor duwe rute pandhuan sing luwes lan rodha lintang sing bisa diganti supaya cocog karo konfigurasi produk

Ndeleng Video

Cekap

- Konsumsi energi sing kurang, throughput sing dhuwur

- Kontrol layar tutul terpadu kanggo gampang digunakake lan produktivitas dhuwur

- Fitur Setel kanggo ngontrol kabeh piston liwat Sistem Servo

- Jilid kanggo saben piston bisa disetel karo siji sentuhan ing layar - ora dibutuhake imbuhan manual

Ndeleng Video

Praktis

- Setelan Manajemen kanthi proteksi sandhi kanggo mbatesi akses

- Kanthi nutupi, gampang ngatur pangowahan cepet

- Dibangun ing castor mobilitas supaya nggunakake lantai lantai sing efisien